Although monolithic aerogels of numerous types and forms have been produced using a broad palette of techniques, it remains a challenge to accurately tailor the micro- and macrostructure of the resulting three-dimensional structures. Recently, researchers from Kansas State University (USA) have presented a 3D-printing freeze drying technique promising just that.

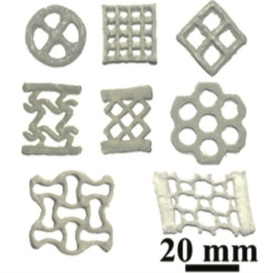

The so-called 3D freeze assembling printing (3DFAP) technique facilitates the fabrication of monolithic aerogels of various macrostructures (see figure on the right). Using this process, the team of researchers was able to produce silver nanowire aerogels (SNWA), that have ultra-low density (1.3 mg/cm3) and high electrical conductivity (0.24 S/cm), while also exhibiting outstanding mechanical features such as good compressive resistance and tunable Poisson ratios (even negative). Experiments investigating the effect of mechanical stress on material resistance revealed outstanding cyclic stability. Furthermore, the different structures were found to exhibit extremely high mechanical resilience, even under tensile stress.

In light of these promising results, the authors conclude that through facilitating the manipulation of the aerogel macrostructure, the novel production technique offers the possibility to manufacture three-dimensional aerogel structures for applications in the fields of sensing, energy storage or catalysis. They are also convinced that the 3DFAP technique can be applied to produce other 3D nanomaterial architectures.

More details: Pengli Yan et. al; 3D Printing Hierarchical Silver Nanowire Aerogel with Highly Compressive Resilience and Tensile Elongation through Tunable Poisson’s Ratio, Small Volume 13, Issue 38 October 11, 2017. http://onlinelibrary.wiley.com/doi/10.1002/smll.201701756/abstract

Read more at: http://www.advancedsciencenews.com/3d-printing-tunable-poisson-ratio-metallic-aerogels/