| Day 2: Tuesday 25 Sept 2018 | |||

| 08:30 – 09:00 | 5-1 | Optimizing Nanomaterials-Based Electrodes for Electrochemical Energy Storage and Conversion Victor A. Beck, Todd Weisgraber, Anna N. Ivanovskaya, Swetha Chandrasekaran, Bryan D. Moran, Seth E. Watts, Dan A. Tortorelli, Juergen Biener, Marcus A. Worsley |

Keynote 2 |

|

Two-dimensional (2D) nanomaterials, such as graphene and transition metal dichalcogenides, hold extraordinary promise for application in a number of electrochemical technologies. Electrochemical energy storage (EES) devices, such as lithium-ion batteries and supercapacitors, in particular, have seen 2D materials integrated into various components with exciting results. In general, EES devices are emerging as primary power sources for global efforts to shift energy dependence from limited fossil fuels towards sustainable and renewable resources. These EES devices, while renowned for their high energy or power densities, portability, and long cycle life, are still facing significant performance hindrance due to manufacturing limitations. One major obstacle is the ability to engineer macroscopic components with designed and highly resolved microstructures with optimal performance, via controllable and scalable manufacturing techniques. 3D printing covers several additive manufacturing methods that enable well-controlled creation of functional materials with 3D architectures, representing a promising approach for fabrication of next-generation EES devices with high performance. Here, we present recent work in fabricating 3D functional electrodes utilizing 3D printing-based methodologies. Specifically, 3D printing techniques such as projection microstereolithography and direct ink writing are described, as well as the details of respective feedstock development efforts. Finally, characterization of the 3D-printed electrodes and their performance in various EES applications will be presented and discussed. |

|||

| 09:00 to 09:20 | 5-2 | Direct Ink Writing of Carbon and Graphene Aerogels Swetha Chandrasekaran, Bin Yao, Tianyu Liu, Wang Xiao, Yu Song, Fang Qian, Cheng Zhu, Eric B. Duoss, Christopher M. Spadaccini, Yat Li, Theodore F. Baumann, Marcus A. Worsley Hajar Maleki, Susan Montes, Nicola Hüsing |

Aerogels f. electrochem. & catalysis |

|

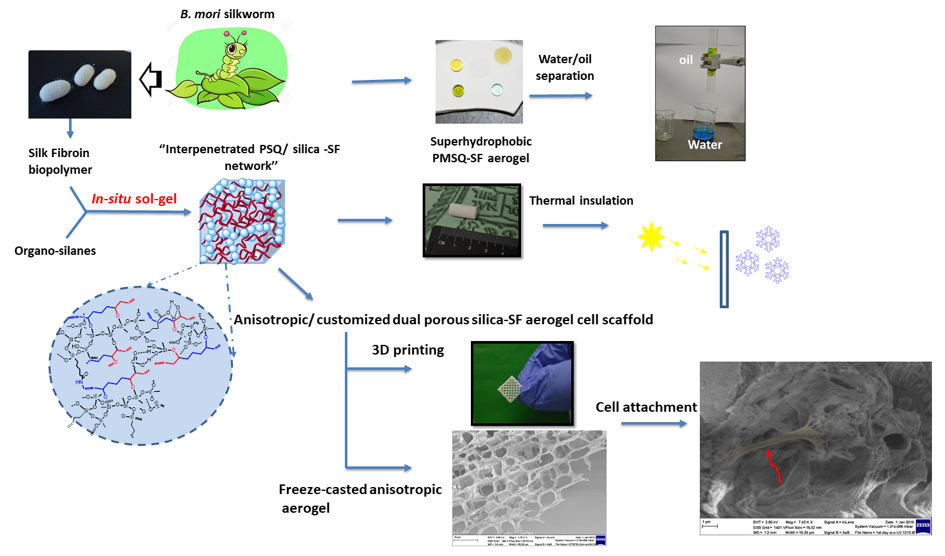

Energy related processes, such as energy storage, catalysis, and desalination typically utilize high surface area electrodes that possess macro- and micropores. One such class of electrode materials are carbon-based aerogels – porous solids with an interconnected network of carbon nanoparticles that exhibit large surface area, high electrical conductivity, and good structural stability. However, the random nature of the pore network in these aerogel materials limits transport of species (e.g. ions, fluids, etc.) through the highly tortuous pore structure. Therefore, the ability to fabricate aerogels with controlled pore sizes and geometries aimed at facilitating species transport should lead to some tangible improvements in the performance and efficiency of carbon aerogel-based electrodes. Our work focuses on 3D printing these aerogels via direct ink writing to precisely deposit inks in a pre-defined tool path to form 3D structures to improve both mass transport and output power efficiency for electro-chemical applications. Developing a feedstock ink composition and tuning their rheological behavior is a key step to forming self-supporting filaments and thereby generate 3D parts. Electrodes with dimension varying from 10’s of mm to cm were printed with the smallest feature size of 100 microns. The 3D printed graphene aerogels can also be used as a scaffold to We have also demonstrated that by using 3D printed graphene aerogels as scaffold, to support ultrahigh mass loadings of pseudocapacitive materials. |

|||

| 09:20 to 09:40 | 5-3 | Electrocatalysis on nanoparticle derived aerogels A. Eychmüller |

|

|

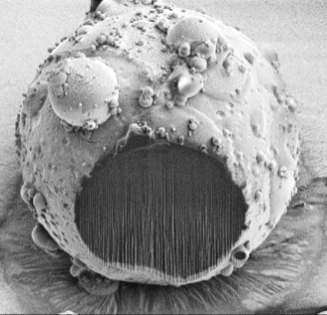

After we summarized our work on the electrocatalysis on (multi-)metallic (aero-)gels we concentrated our work on the amelioration of the building blocks as a plausible approach to graft aerogels with distinguished properties while preserving the aerogel superiority. We report on the first case of an aerogel electrocatalyst composed entirely of alloyed PdNi hollow nanospheres with controllable chemical composition and shell thickness. This work expands the exploitation approach of electrocatalytic properties of aerogels into morphology and composition control of its building blocks. In a further study, we prepared and analyzed a new class of hierarchical aerogels composed of multimetallic Ni-PdxPtynanoparticle building blocks with continuously engineered shape and compositions. This approach results in aerogels with hierarchical structures organizing the nanoscale regulated architecture and macroscale three-dimensional network structure. In a final example we`ll line out how core-shell structuring of pure metallic aerogels can be tuned towards highly efficient Pt utilization for the oxygen reduction reaction. |

|||

| 09:40 to 10:00 | 5-4 | Multicompound Gel Networks of Nanoparticles for Photoelectrochemical Applications Marina Rosebrock, Jan Miethe, Pascal Rusch, Anja Schlosser and Nadja-C. Bigall |

|

|

As a strategy for use of nanoparticles to form self-supporting superstructures, a gelation process is appropriate. Nanoparticles are well researched compounds with controllable size and shape . A large number of materials is suitable for nanoparticle synthesis. The difference of properties between nanoparticles and their bulk material leads to interesting phenomena like sizedepending band gaps. Accordingly, nanoparticles are part of a large research area. A big improvement of material properties is the combination of different materials on the nanoscale. For this objective, a multicompound superstructure system of semiconductor and metal nanoparticles provides application-oriented properties. The main fields of application are photoconducting systems and photocatalysis. By illumination of the semiconductor compound an exciton is generated. The contact to a metal compound will force the electron to go to the metal domain while the hole is fixed to the semiconductor. A charge carrier separation occurs and can be used for oxidation (hole) and reduction (electron). The above-mentioned system is composed of CdSe/CdS nanorods and noble metal nanoparticles as two different compounds in a gel network. |

|||

| 10:00 to 10:20 | 5-5 | Ultra-Low-Density Metal Nanowire Aerogels Tyler M. Fears, Fang Qian, Tom Braun, Alyssa L. Troksa, Joshua A. Hammons, Michael H. Nielsen, Jean-Baptiste Forien, Theodore F. Baumann, T. Yong-Jin Han, Sergei O. Kucheyev, and Michael Bagge-Hansen |

|

|

Nanoporous metal aerogels are desirable for a number of applications in materials for energy storage, generation, and utilization. Metal aerogels in the ultra-low-density regime (<20 mg/cm3) are particularly difficult to fabricate, especially as well-defined monoliths. One recent effort to produce new metal aerogels has proven uniquely successful at producing metal aerogels to the desired specifications. This strategy involves freezing suspensions of high-aspect-ratio (a ≈ 1000) metal nanowires then removing the solidified matrix, via freeze-drying or freeze-extraction, depending on the solid matrix. As such, the porosity in the final aerogel is intrinsically linked to solvent freezing physics and is highly sensitive to the conditions under which it takes place, e.g., temperature, solvent composition, and sample geometry. Herein will be discussed efforts at Lawrence Livermore National Laboratory to produce high-quality metal aerogels, especially our recent success in producing 1-100 mg/cm3Au aerogels (ρrel< 0.5%). Special emphasis will be placed on complementary in situ/ex situ analysis of hierarchical porosity (3 nm – 100 µm) in these aerogels and structural evolution during freeze-casting and drying. |

|||

| Coffee Break 10:20 – 10:50 | |||

| 10:50 to 11:10 | 6-1 | Mapping Catalytic Performance of Nickel Nanowires Immobilised in Silica Aerogels for CO2 Hydration Reaction Khalil T. Hassan, Jiabin Wang, Xiao Han, Jon J Sharp, Gaurav A. Bhaduri, Vladimir Martis and Lidija Šiller C. Balzer, S. Zhao, G. Reichenauer |

Aerogels f. electrochem. & catalysis |

|

The rise in atmospheric carbon dioxide (CO2) is a major factor responsible for increasing global surface temperature. A possible solution to mitigate climate change is CO2capture, storage and utilization (CCSU). Many technologies such as absorption, desorption, chemical looping combustion, membrane separation, hydrate-based separation and cryogenic distillation have been developed to isolate CO2from flue gas streams. Another promising CCSU technology is removing the CO2by utilizing the CO2hydration reaction.However,in the absence of a catalyst the reaction is slow.At Newcastle University (UK) we have discovered experimentally that nickel nanoparticles (NiNPs) are first inorganic heterogeneous catalysts that catalyses the CO2hydration reaction (CHR). In this work, we have investigated immobilised nickel nanowires (NiNWs) as 1D nanomaterials on silica aerogels as a heterogeneous catalyst for the CHR and compared them with NiNPs (as 0D nanomaterial). The catalytic activity was investigated in a vapor phase monitoring adsorption-desorption kinetics and isotherms, using a dynamic vapor sorption analyser (DVS Vacuum). DVS Vacuum analysis were used to study the co-sorption behavior at high concentration levels of CO2with water vapor. |

|||

| 11:10 to 11:30 | 6-2 | Aerogel-like composite catalysts synthesized via advanced approaches combining sol-gel and SCF methods N.S. Nesterov, A.S. Shalygin, O.N. Martyanov |

|

|

SCF technologies are proven to be an efficient tool for the synthesis of various functional materials possessing unique properties. At the same time, the number of method for the synthesis of the real industrial catalysts based on SCF is rather limited despite the combination of SCF properties allow one to obtain catalysts displaying unique selectivity and activity in a number of processes. The efficiency of heterogeneous catalysts is largely determined by the support (matrix), which provides dispersion, stability and accessibility of the active phase. Aerogel based materials are promising candidates to immobilize active phasedue to their high specific surface area and open pore structure. Developing the aerogel based catalystit is necessary to remember that viable catalytic processes implies the solution of many problems including not just high activity, but also selectivity, mass and heat transfer issue, the stability of the active phase, morphology of the matrix and many others. In this regards only the comprehensive analysis of the properties of aerogel-like composite catalysts can give us a new ‘brand’. Here we report the original approaches to synthesize the aerogel-like composite catalysts based on alumina and silica as a matrix. Using Ni-Cu system as an example it is shown that the silica framework formed in SC CO2conditions allows one to synthesize the active catalysts with highly dispersed (few nanometers) active bimetallic phase without phase separation. The oxide matrix prevents the sintering of metal particles, increases the dispersion and specific surface area, as well as accessibility of active phase. Also the novel approach for the synthesis of silica aerogel composites via sol-gel method and subsequent drying in SC CO2creates the great potential to use a wide range of MOFs in continuous flow catalysis and separation processes. |

|||

| 11:30 to 11:50 | 6-3 | Carbon aerogels as cathode matrix for lithium-sulfur batteries Marina Schwan, Barbara Milow, Frieder Warth, and Norbert Wagner |

|

|

The exploitation of renewable energy resources and energy storage became an important issue in the last decades. The lithium-sulfur batteries are very attractive due to their very high theoretical specific capacity of 1675 mAh/g and very high specific energy density of 2500 Wh/kg. In addition to these values, sulfur is abundant on earth and inexpensive. With these benefits lithium-sulfur batteries are considered to be the next generation power source in advanced technologies. However, the poor cycle stability caused by polysulfide shuttle and side reactions reduces the active mass quantity resulting in decrease of capacity. Furthermore the volume expansion on the cathode side of about 80 % leads to crack formation and is referred to decrease of capacity. Carbon aerogels are promising materials to be used as cathode matrix for lithium-sulfur batteries. They are carbonized from organic resorcinol-formaldehyde aerogels and exhibit as a highly porous structure with porosities up to 98 %, high surface areas of around 500-3500 m²/ and large total pore volumes of around 2-3 cm³/g. In the presentation the influence of the pore structure and the pore volume distribution on the efficiency of such Li-S-battery systems will be discussed. In addition effects of pulverizing methods, such as ball mill and grinding, on the microstructure of the carbon aerogels will be addressed. The differences between carbon aerogels with different mechanical strength – from very hard to flexible – will be compared and analyzed for batteries application. The effects on the electrochemical properties of the built cells caused by the developed carbon aerogels will be presented. |

|||

| 11:50 to 12:10 | 6-4 | Manganese oxides aerogels and nanoparticles obtained in a one-pot one-step process directly in supercritical CO2 I.V. Elmanovich, V.V. Zefirov, M.O. Gallyamov |

|

|

Manganese oxides are known to be electrocatalytically active in an oxygen reduction reaction (ORR) in alkaline media. That makes them a great alternative to expensive Pt-containing electrocatalysts for such energy storing devices as alkaline fuel cells or lithium-air batteries. One of the main requirements for the electrocatalysts is their high specific surface area. In this work we propose a new approach to synthesizing manganese oxides with high specific surface area viathermal decomposition of manganese organometallic precursors directly in oxygen enriched supercritical carbon dioxide. We demonstrate that using this strategy one can obtain both monodispersed manganese oxides nanoparticles and monolithic aerogels in a one-pot one-step process. Monolithic aerogels are formed when dimanganese decacarbonyl (Mn2(CO)10) is used as a precursor, while cyclopentadienylmanganese tricarbonyl (CpMn(CO)3) yields monodispersed nanoparticles. Morphology of the obtained nanoparticles and aerogels was studied by means of TEM and SEM. It was revealed that when nanoparticles are formed from CpMn(CO)3their sizes vary from 50 to 100 nm. When monolithic aerogels are formed, they consist of nanoparticles with average sizes of 5–10 nm. Electrochemical measurement confirm that the synthesized materials can be used as electrocatalysts for ORR in alkaline media. We believe that the fact that monolithic aerogels are formed in a matter of hours without the need to perform solvent change or drying procedure, the proposed approach to synthesis of metal oxide aerogels is a promising one and needs further exploration. |

|||

| 12:10 to 13:10 | Poster Speed Presentations (EVEN Poster numbers, 1 slide, 90 sec) | ||

| LUNCH AND POSTER SESSION (EVEN Poster numbers) 13:10 – 14:50 | |||

| 14:50 to 15:10 | 7-1 | Automotive Engine Covers Made From Mechanically Strong Monolithic Polymer Aerogels Ryan T. Nelson, Justin S. Griffin, Alper Kiziltas, Deborah Mielewski, and Stephen A. Steiner III |

Aerogel applications |

|

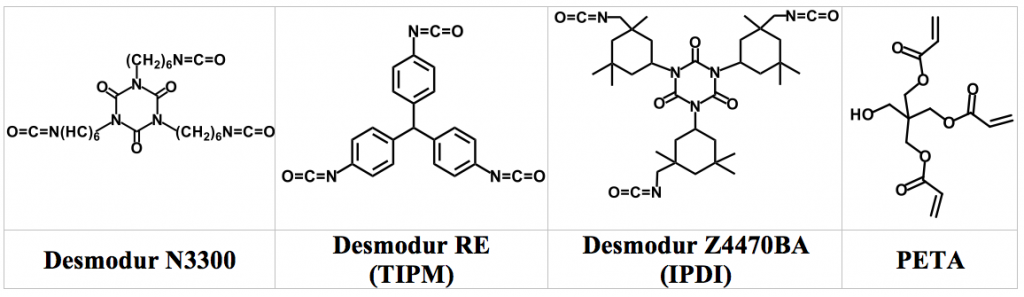

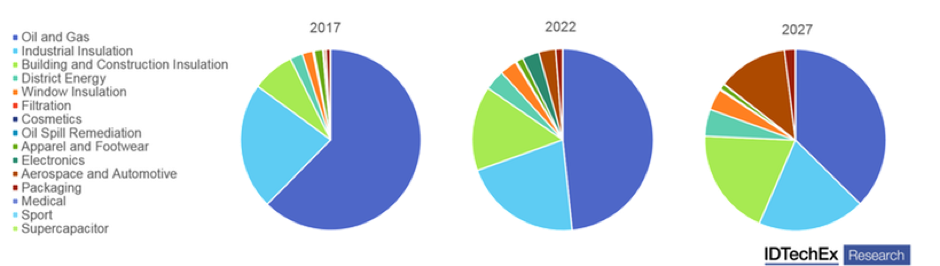

The ever-increasing demand for improving the fuel efficiency of fuel-powered automotive vehicles places increasingly daunting requirements on materials used in engine compartments. Increasing vehicle fuel efficiency means running engines hotter while simultaneously decreasing vehicle size and weight, thereby putting increasing thermomechanical demands on engine compartment components. As a result, engine compartment materials need to be increasingly thinner, lighter, and more multifunctional at hotter temperatures. Sitting atop the engine in the engine compartment are an engine cover and NVH (noise, vibration, harshness) pad that serve to thermally isolate the engine from other engine compartment components and to keep engine noise and vibration from reaching the cabin interior. The engine cover assembly must also have high-temperature tolerance and be mechanically robust enough to withstand normal use and vehicle maintenance. In addition, these functions must be achieved in the limited free space of the engine compartment. Existing technology is based on polyurethanes with upper an operating temperature of 130°C and is inadequate for the temperatures demanded by the next generation of vehicles. Aerogel Technologies and Ford have partnered to create a new generation of aerogel-based engine covers to replace existing hard and soft engine covers in Ford’s vehicles. Current commercially available aerogel materials are unacceptable for use in engine compartments due to particle shedding and lack of structural functionalities. Airloy®aerogels from Aerogel Technologies are a new class of mechanically strong polymer aerogels that combine the strength and durability expected of engineering materials with the thermal insulating properties of traditional aerogels while simultaneously offering chemical and water resistance, operating temperatures up to 300°C, high sound transmission loss, and excellent vibration mitigation. Technical considerations underlying the development of an aerogel-based engine cover will be presented including aerogel formulation and materials properties considerations, shape control requirements, cost projections, and plans for future scale. |

|||

| 15:10 to 15:30 | 7-2 | Ceria-containing Catalytic Aerogels for Applications in Automotive Pollution Mitigation Mary K. Carroll, Ann M. Anderson, Luisa F. Posada, Xiao Peng Li, Thomas F. Andre,1 Bradford A. Bruno |

|

|

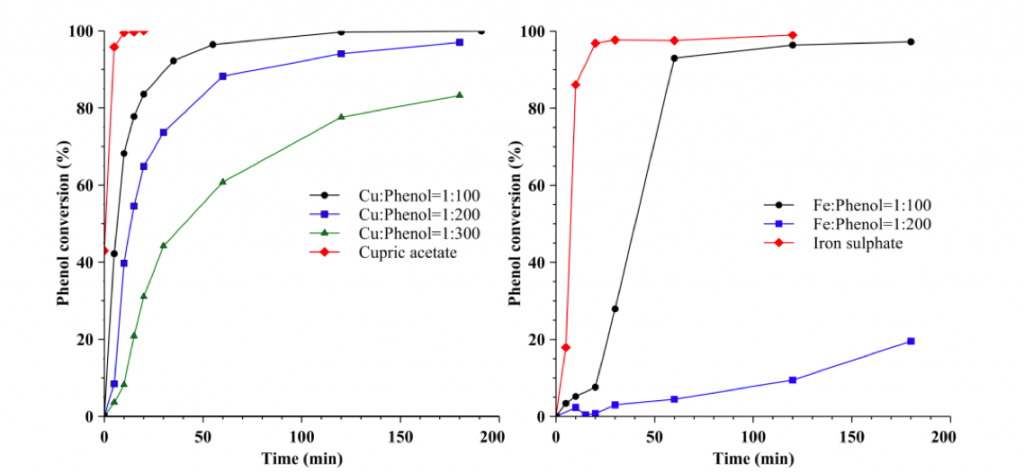

Aerogels show great promise as heterogeneous catalysts for a wide variety of applications due to their combination of unique physical properties: nanoporous structures with high surface area and good thermal stability. By replacing precious metal catalysts, tailored catalytic aerogel materials have potential to provide a sustainable approach to the after-treatment of automotive (internal combustion engine) exhaust, which requires simultaneous reduction of nitrogen oxides and oxidation of carbon monoxide and unburned hydrocarbons. In prior work, we have incorporated several metal species into an alumina or silica aerogel backbone via co-precursor and impregnation methods, and have developed a catalytic testbed to evaluate the catalytic performance of these materials under conditions that simulate those experienced in a catalytic converter. In particular, copper-alumina and copper-silica aerogels were shown to be effective at catalyzing the reduction of NO and the oxidation of propane and CO under conditions similar to those experienced by automotive three-way catalysts (TWCs). There is extensive literature on the use of ceria-based materials for oxygen storage to enhance the performance of TWCs. In this presentation, we focus on the development and characterization of a series of ceria-containing aerogels for synergistic benefits of catalytic performance. These materials, prepared via a rapid supercritical extraction (RSCE) process, include ceria-alumina, ceria-silica, ceria-copper-alumina, and ceria-copper-silica RSCE aerogels. Synthetic approaches, physical characterization (including IR, XRD, SEM/EDX) and catalytic performance of these ceria-containing catalytic aerogels will be presented. |

|||

| 15:30 to 15:50 | 7-3 | Extending applicability of colloidal nanoparticle-based aerogels: mixed and hybrid structures as well as processable inks N.Gaponik |

|

|

The aerogels built from colloidal nanoparticles attracted great attention during last 10-15 years. As they can be fabricated by the gelation of preliminary prepared colloidal solutions, the varying of the solution content may allow precisely controlling their composition. This presentation will overview the methods of the hybridization of inorganic and organic components as well as the mixing of semiconductors and metals to build various multifunctional gelated nanostructures. Possible applications of combined functionalities as well as the appearance of an added functionality will be discussed. The applicability of gels and aerogels may be greatly extended by converting them into solution-processable inks. |

|||

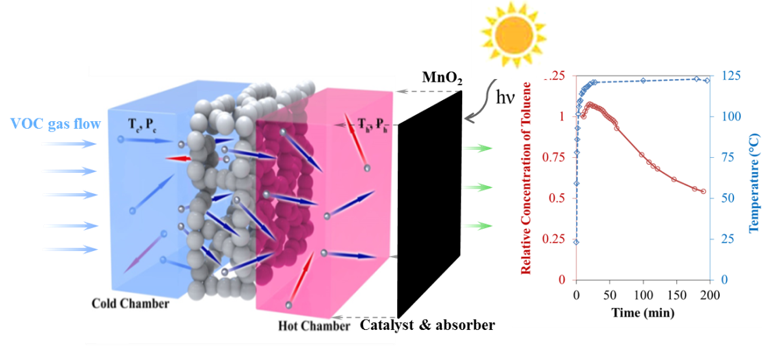

| 15:50 to 16:10 | 7-4 | Aerogel-based, light-driven gas pump and VOC removal Shanyu Zhao, Sarka Drdova, Olivier Emery, Matthias M. Koebel, Jing Wang , Wim J. Malfait |

|

|

Thermal transpiration gas pumping, a bioinspired technology derived from botany, is attractive for developing gas compressors, pressure generators or gas separators with potential applications for gas sampling, global positioning systems, fuel cells and micro-combustion devices. Knudsen pumps rely on a thermal gradient across an insulating, porous material to drive the flow of gas molecules from the cold to the hot side of the membrane. Normally, Knudsen pumps need an external power supply, e.g. a resistive heater, to generate the temperature gradient. Recently, we developed a light-driven thermal transpiration pump prototype by co-gelating silica aerogel with (black) Ramsdellite MnO2. Benefiting from the excellent photo-thermal conversion efficiency of the MnO2absorber layer, the local temperature could rise as high as ~250°C, with a ~150°C temperature difference across the (insulating) silica aerogel layer, and generate ~570 Pa of pressure head. Furthermore, R-MnO2exhibits highly efficient catalytic activity for the degradation of organic compounds, e.g. benzene derivatives, under full solar spectrum irradiation. Benefiting from the dual function of R-MnO2, a test experiment where R-MnO2was incorporated into a silica aerogel membrane and without an external pump was performed. The thermal transpiration was sufficient to drive a gas flow through the membrane and the catalytic R-MnO2layer into the GC for analysis. A partial conversion of toluene was observed, providing proof-of-concept of simultaneous light-driven pumping and photo-catalytic VOC degradation for a future fully passive air purification system. |

|||

| 16:10 to 16:30 | 7-5 | Applications of Aerogel Technology to Current Biomedical Demands Carlos A. García-González, Angel Concheiro, Jose L. Gómez-Amoza, Carmen Alvarez-Lorenzo |

|

| Society is demanding new or improved biomedical solutions derived from the new demographic scenario (population ageing) and social habits (sedentary lifestyle) worldwide. Linked to this new social context, (i) the increased demand for bone grafts, (ii) the search for advanced treatments for chronic wounds, and (iii) the need for improved patient adherence to medication, are among the biomedical consequences with higher relevance. In this work, the unique properties of aerogels are exploited for the development of materials suitable for the abovementioned applications. (i) For regenerative medicine, synthetic scaffolds loaded with bioactive agents and aerogel particles were processed by supercritical foaming. In vitroand in vivostudies highlighted the relevance of aerogels in shaping the porous structure of the scaffolds and in favoring biological tissue integration. (ii) For wound healing, multilayered dressings containing aerogels were processed and resulted advantageous in providing a suitable local treatment at the wound site in terms of exudate management and oxygen permeability with no interference with the normal healing process. (iii) Finally, the high porosity and low density of aerogel particles provide them with excellent aerodynamic properties for their use as drug carriers for pulmonary delivery by oral inhalation, a non-invasive administration route. Digitally controlled aerogel printing is herein presented as a novel process for the production of particulate carriers for the pulmonary route with narrow particle size distribution and high spatial resolution. | |||

| 16:30 to 16:50 | 7-6 | Pectin-xanthan aerogel coatings on medical grade stainless steel for hip implants Zoran Novak, Gabrijela Horvat, Željko Knez, Lidija Gradišnik, Uroš Maver, Klodian Xhanari, Majaž Finšgar |

|

|

Polysaccharides were found to be highly promising materials for the use in orthopaedics regarding their improved implant integration, biodegradability and biocompatibility. Therefore, in this research we developed a new material for the potential use as hip implants. We prepared a pectin-xanthan composite aerogel on passivated medical grade stainless steel. The aerogel coating was prepared in ethanol by a method we developed and described in one of our recent papers. For this study we chose xanthan and pectin, based on the results that we published in the recent paper. Initially we determined the proper ratio among two polysaccharides in order to achieve good adhesion on the medical grade stainless steel. We also used two model drugs, diclofenac sodium and indomethacin, respectively in order to obtain final drug loaded coatings for local drug delivery. Prepared coatings were dried under supercritical conditions of CO2. Electrochemical analysis was performed on the final samples and the results showed that all passivated samples were highly resistant to general corrosion.In-vitro dissolution tests showed the prolonged drug release of both model drugs up to 24 h. Both drug releases were completed after 24, additionally confirmed by IR spectroscopy after the final release point. The potential of samples for use in orthopedic applications was evaluated on a human bone-derived osteoblast cell and all samples were shown to be biocompatible. Moreover, the increased viability of some samples is a very promising start for the future research and possible clinical use of those materials.

|

|||

| Coffee Break 16:50 – 17:10 | |||

| 17:10 to 17:30 | 8-1 | Polymerization induced phase separation – a mechanism for structure formation in aerogels? Lorenz Ratke, Fei Wang and Britta Nestler |

Modelling of aerogel formation & processing |

|

Many aerogel forming solutions start with a perfect mixture of monomers in a solvent like water and alcohols. The monomers react forming oligomers of different degrees of polymerization. In contrast to the monomers these are not miscible with the solvent: a time dependent miscibility gap forms. In as much as the degree of polymerization becomes higher, the critical temperature of the miscibility gap increases. Eventually the operation point of the solution of polymers and solvent matrix crosses the binodal line and a phase separation proceeds, using the already formed oligomers as pre-nucleation sites. Once these droplets of a polymer rich phase appear in the solution, they, however, directly transform via a percolation transition into solid-like particles. These primary particles can form a network by several mechanisms discussed intensively in the literature like DLA, DCLA, sedimentation, shear flows etc. Depending on the speed of polymerization, however, the system might not only pass the binodal, but also the spinodal line either rapidly or consecutive following nucleation events. Then spinodal decomposition finishes the phase separation and structure formation in gels, which upon a suitable drying can be converted to aerogels. We have set up a non-linear Cahn-Hilliard like model to describe the above scenario of structure formation using the Flory-Huggins expression for the bulk free energy of the polymer mixture and its dependence on the degree of polymerization. The presentation will describe the basic assumptions of the model, its mathematical background and first results using numerical solutions of the set of equations derived. |

|||

| 17:30 to 17:50 | 8-2 | Insights into molecular mechanics of nanostructured porous silica aerogel Sandeep P. Patil, Ameya Rege, Mikhail Itskov, and Bernd Markert |

|

|

In this work, the mechanical properties of silica aerogels have been studied with Molecular dynamics (MD) simulations. In the first part, the silica aerogel model of 192000 atoms was created with different densities by direct expansion of beta-cristobalite, along with series of thermal treatments. Due to a high number of atoms and improved modelling, the proposed model showed the significant improvement in the stress-strain curves and more stable and repeatable MD simulations. The moduli of the aerogel model materials display a power law dependence on density with the exponential value was estimated to be ~3.25. The samples studied showed two different types of mechanical behaviours in tension; the low-density aerogels were more ductile, while the denser aerogels behaved as brittle materials. In the compression simulations of aerogels, deformation occurred without a significant increase in stress for low densities, however, for high densities, atoms offered the high resistance to the movement; hence, the densification obtained very early. The relationship between different mechanical parameters has been found in the consecutive unloading and reloading simulations of different aerogel densities. In the second part, MD simulations with the model size up to ~5.07 million atoms have been performed to investigate the effect of crack length to height ratio on fracture strength, fracture toughness and strain energy release rate. For a considered density range of 295-1155 kg m-3, the fracture toughness and the strain energy release rate at the onset of the crack propagation increases with increasing crack length to height ratio. The fracture toughness and the strain energy release rate of the silica aerogel model displays a power law dependence on the density, with the exponential values estimated to be ~2.02 and ~1.16, respectively. Our study reveals a more comprehensive understanding of the mechanical behaviour and properties of silica aerogels at the nanoscale. |

|||

| 17:50 to 18:10 | 8-3 | Molecular modelling study of organically-modified silica aerogels Pedro Maximiano, Luísa Durães, Pedro N. Simões |

|

|

Even though silica aerogels exhibit outstanding properties, with wide-ranging applications, these materials possess a number of issues which limit their large scale production, particularly poor mechanical resistance and particle shedding. The addition of polymers to the silica matrix is a widely studied procedure to avoid such issues. In order to promote strong bonding between the polymer chains and the silica aerogel matrix, it is often necessary to introduce functional groups in the matrix that can interact with the polymer, either by surface modification or by synthesis with appropriate co-precursors. The resulting organically-modified silica (ORMOSIL) aerogels and their composites have improved structural properties when compared to unmodified aerogels. However, the first stages of the growth of the silica matrix in these materials (at the nanoscale) and the interactions between that matrix and the polymer chains are not completely understood. Molecular modelling and simulation (MM&S) provides a systematic approach for gaining insights on these questions, as it can be used to describe the physicochemical phenomena inherent to these systems, complementing the limited information from experimental data. MM&S has been gaining ground on both academic and industrial circles, as a standard product design tool. Although there are already several computational studies of unmodified silica aerogels (i.e.those derived from tetramethyl/ tetraethylorthosilicate), investigations on ORMOSIL aerogels are lacking. In this context, we have used quantum mechanics DFT calculations to model ORMOSIL aerogels of various compositions. By comparing theoretical IR and NMR spectra derived from these calculations with their experimental counterparts, we have constructed a reasonable microscopic model for these materials. |

|||

| 18:10 to 18:30 | 8-4 | Modelling the mechanical behaviour of dry and wet polysaccharide based aerogels Ameya Rege and Mikhail Itskov |

|

|

The literature on models describing the mechanical properties of polysaccharide based aerogels is not very extensive. Such aerogels have been attracting much attention in recent years, given their bio-compatibility and bio-degradability. Being potential candidates for many biomedical applications, their mechanical behaviour and structural integrity have become state of the art issues that need thorough investigations. The mechanical behaviour of cellulose aerogels has recently been analysed and studied, via micro-mechanical modelling, under compression and tension. These aerogels are characterised by a cellular morphology, wherein under loading the microcells undergo bending and stretching (or compression). This behaviour is captured using the Euler-Bernoulli beam theory. Under tension, the standard theory suffices as the material sustains only small strains before failure, which is accurately predicted by the model. However, under compression, the extended version of the theory is applied and a new strain energy density function is proposed. The model includes only six physically motivated parameters. Finally, the model is validated against experimental data from polysaccharide based aerogels, such as cellulose, pectin and κ-carrageenan aerogels. Furthermore, the proposed approach is also used to describe the mechanical behaviour of wet aerogels. Studies on wetting of polysaccharide based aerogels are motivated by potential tissue engineering applications. A network decomposition concept is introduced and the resulting model is shown to accurately predict, both qualitatively and quantitatively, the stiffening in the network response upon wetting. |

|||

| 18:30 to 18:50 | 8-5 | Thermal conductivity of bio-aerogels Sophie Groult, Lucile Druel, Cyriel Rudaz, Tatiana Budtova |

|

|

Aerogels are ultra-light weight and highly porous nanostructured materials, with open pores and high specific surface area. Classical aerogels are based on silica or synthetic polymers (for example, polyurethanes). At the beginning of the 21stcentury a new class of aerogels was born, based on polysaccharides: bio-aerogels. One of the extraordinary properties of aerogels is their low thermal conductivity which can be lower than that of air in ambient conditions (0.025 W/m.K), making them thermal super-insulating materials. Such materials prevent energy losses which is crucial in buildings, appliances and transport (refrigerated tracks) industrial sectors. Thermal super-insulation can be reached in mesoporous materials with low density. Does it work for bio-aerogels? Literature on this topic is rather scarce. In this presentation a review of the thermal properties of bio-aerogels will be made. Literature results will be compared with the new ones obtained recently in our laboratory on starch and pectin aerogels. Problems, prospects and open questions will be discussed. |

|||

| Day 3: Wednesday 26 Sept 2018 | |||

| 08:30 to 08:50 | 9-1 | Supercritical drying of aerogels – Thermodynamic considerations for critical process steps André Mohs, Volkmar Steinhagen |

Supercritical drying |

|

The aerogel drying process can be considered the most critical step when it comes to the generation of aerogels. Although there are different approaches for this process step, the most common process in larger scale is the drying of the aerogel by exchanging the solvent inside of the material (in most cases an organic solvent like ethanol, acetone, etc.) with supercritical CO2and expanding it to the gaseous phase in an additional process step without passing the two-phase region. The equipment for this process resembles in many ways the equipment which is used for extraction processes of natural raw materials with supercritical CO2. The benefit in using this type of equipment is that it has already been used for a variety of products with different capacities within the past 4 decades so the design and reliability of such equipment is well established. However, due to the large amount of organic solvent in the process, there are some major differences to be kept in mind when it comes to process development for the drying process of aerogels. The largest difference lies in the properties of the solvent mixture, which vary strongly with composition and process conditions and thus cannot be considered to be equal to pure CO2or to pure solvent properties. This presentation gives an overview on some critical process steps of the aerogel drying, where the knowledge of thermodynamic behavior is essential for process development. Furthermore, thermodynamic based side-effects during the operation of such a drying plant will be presented. A short overview on cost drivers with regard to process changes due to thermodynamic behavior of the CO2-solvent mixture are discussed as well. |

|||

| 08:50 to 9:10 | 9-2 | Reduction of compression requirements during aerogel production Alberto Bueno, Ilka Selmer, Raman S.P., Pavel Gurikov, Wibke Lölsberg, Dirk Weinrich, Marc Fricke, Irina Smirnova |

|

|

Production of aerogels starting from almost all precursors requires a supercritical drying step to preserve the mesoporous structure of the gel. Such systems include most of the organic gels derived from synthetic polymers and almost all biopolymers. Supercritical drying, which requires high pressures, increases the initial capital expenditure for the production facility. A common practice in the industry and research facilities is to divide the supercritical drying process into three main steps: pressurisation, extraction and depressurisation. The pressurization and depressurisationare considered dead times since the common though is that no solvent can be extracted during these stages. To avoid crossing the two-phase region of the system during the pressurisation, this step is don eas fast as possible and without extracting solvent out of the autoclave. This practice requires significant compression capabilities which translate to considerable capital costs. Meanwhile, the rate of depressurization step depends mainly on the nature of the material. Integrating the pressurization and the extraction into one efficient extraction step would require smaller compression requirements reducing the capital expenses and thus making it more attractive to the industry. The reduction of compression requirements is achieved by reducing the pressurisation rate considerably. By taking advantage of the solvent expansion phenomena,it is possible to cross the two-phase region during the pressurisation. The relative volume expansion of the solvent that is contained inside the gel creates a convective flow which avoids the gas/liquid interface to propagate into the pore structure and permit us to remove the spilt solvent out of the autoclave. Here, we present the first evidence of solvent spillage during the pressurization of the autoclave. |

|||

| 09:10 to 09:30 | 9-3 | Investigation of External Mass Transfer Effects in Supercritical Drying of Alcogel Particles İbrahim Şahin, Erdal Uzunlar, Can Erkey |

|

|

Organic aerogels in the form of particles are considered as promising materials for a wide variety of applications such as drug delivery, biosensing and food technology due their unique properties and biocompatibility. Supercritical drying of wet gels to obtain aerogel particles by removing the pore filling solvent occurs via several mass transport mechanisms and is a crucial step to preserve the desired material properties such as high porosity, high surface area and low density. Models for predicting the kinetics of this process are very beneficial for design and optimization of industrial scale supercritical drying units. Previous studies on kinetics of supercritical drying have been generally limited to drying of inorganic gels in the forms of monoliths. Therefore, there is a need to study the drying of wet gels in the form of particles. In this study, we investigated supercritical drying of alginate gel particles in a packed bed as a model system. Spherical calcium alginate hydrogel particles were prepared by dripping a 1.5 wt% aqueous alginate solution into a 0.2M aqueous CaCl2solution. The hydrogel particles were subjected to a stepwise solvent exchange procedure with ethanol before supercritical drying. The effects of operating conditions and gel dimensions on the drying kinetics were investigated in detail. Drying temperature, pressure and CO2 flow rate were varied between 310 – 355 K, 85 – 170 bar and 2- 4 NL/min. A drying model which takes into account diffusion of the solvent inside the pores, external mass transfer of the solvent from the surface of the gel particles into the flowing CO2stream, and convection and axial dispersion of the solvent in the flowing stream was developed. By fitting the model to experimental data, a correlation for predicting external mass transfer coefficients for supercritical drying of spherical alcogel particles at a wide range of conditions was developed. A good agreement between the experimental data and model results was observed using this correlation. |

|||

| 09:30 to 09:50 | 9-4 | Modeling and scale up of supercritical drying process Lebedev A.E., Khudeev I.I., Menshutina N.V. |

|

|

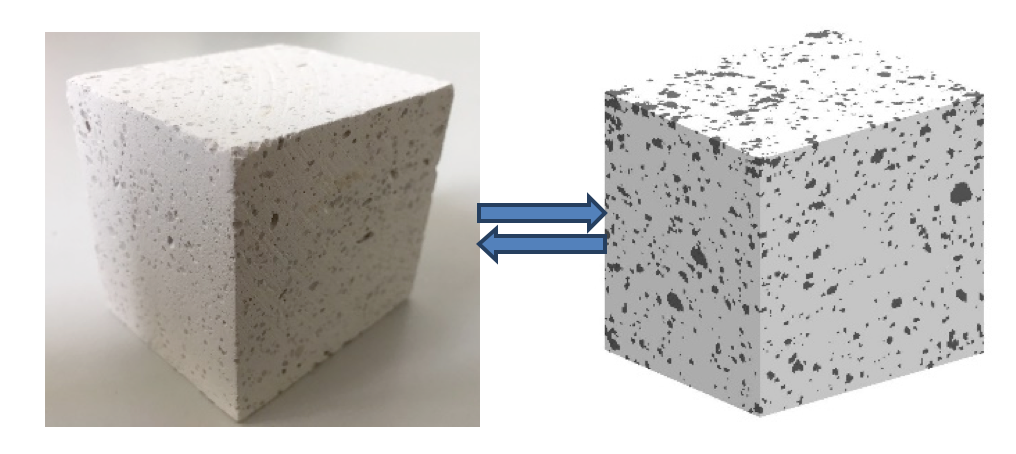

One of the main stages of producing aerogels, promising highly porous materials, is supercritical drying.This stage is the most difficult from the technological point of view, it takes a considerable time and requires the use of high pressure apparatuses. The course of the supercritical drying process is determined by the intensity of heat and mass transfer within the gel, is affected by the hydrodynamic situation inside the apparatus. Methods of mathematical modeling and similarity theory should be used to take into account all significant phenomena and predict the supercritical drying progress with the aim of increasing its efficiency and scaling. It is necessary, on the one hand, to reduce the time of the process while maintaining the quality of the final material, and on the other hand to minimize the costs of the process. Moreover, the obtained regularities should be transferred to apparatuses of an industrial scale. In the framework of this research the kinetics of the supercritical drying process in apparatuses 0.25 L and 2 L was experimentally investigated. The main regularities of the process at its various stages are revealed, the influence of parameters and the hydrodynamic situation is reflected. The most significant parameters of the process are determined with increasing the volume of the apparatus. Hydrodynamics, the phenomena of heat and mass transfer are studied using the CFD method. This method is based on the provisions of continuum mechanics, it allows to study the course of the process in each point of the apparatus at the arbitrary boundary and initial conditions. Based on these results a simplified model of the supercritical drying process is proposed. It can be used to conduct preliminary technological calculations in the development of aerogel production. |

|||

| 09:50 to 10:10 | 10-1 | Recent Developments of Transparent Chitosan Aerogel Satoru Takeshita, Satoshi Yoda |

Biopolymer aerogels |

|

As the industrial feasibility becomes more and more important in aerogel research, major interests in this field have expanded into non-monolithic and/or non-silica materials, such as fast ambient pressure drying of granular aerogels, rapid supercritical drying of microspherical organic aerogels, and silicone-based organic/inorganic hybrid aerogels. Biobased nanofibrous aerogels are also ones of the emerging topics because of their unique physicochemical properties, biocompatibility, environmental friendliness, and abundant resources, but their industrial potential for practical applications is still under study. We have focused on cross-linked chitosan aerogel and studied its potential as transparent thermal insulators for window application, where monolithic silica aerogels have not commercially succeeded so far. Translucent aerogel constructed from a three-dimensional network of chitosan nanofibers is prepared by supercritical drying of cross-linked chitosan organogel. This aerogel exhibits optical transparency and a low thermal conductivity in addition to mechanical toughness that cannot be achieved with conventional silica aerogels. We also reported hydrophobic modifications of the chitosan aerogel using alkylaldehydes and trimethylsilyl groups to improve the humidity stability for practical uses. In this presentation, we summarize the recent developments of chitosan aerogel and introduce some latest topics, including large sample preparation for accurate thermal conductivity measurement (0.016 W m−1 K−1), compositing with luminescent nanoparticles for sensing application, and some preliminary attempts for fast supercritical drying. |

|||

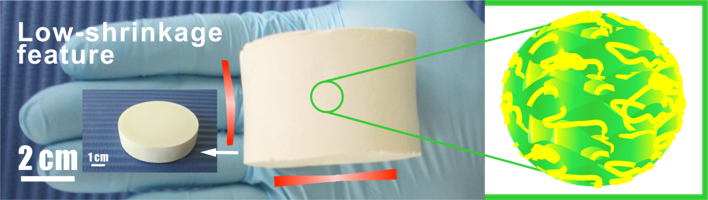

| 10:10 to 10:30 | 10-2 | Chitosan aerogels with skeletal molecular-level enhancement Sizhao Zhang, Junzong Feng, Liangjun Li, Yonggang Jiang, Jian Feng |

|

|

Naturally-occurring biomass aerogelswould be a major viable and cost-effective insulating materialsto reduce greatly the overall carbon footprint and relieve the ecological loadin building energy-saving.However, the significant shrinkage of natural-origin organic-nature aerogels, from its final wet gel to aerogel, remains a formidable challenge. Here we explore a strategy based on supramolecular interaction and covalent crosslinking to overcome the inherent large shrinkage of chitosan aerogel, by using linear polymer enhancement in molecular level. The introduction of linear polyvinyl alcohol (PVA) chains can adequately interpenetrate with crosslinked chitosan chains to form strong intermolecular network architecture. Chitosan aerogel trussed with PVA enables to be readily fine-tuned, simultaneously giving rise to nano-sized cellular voids within the aerogel. Chitosan aerogel obtained shows good heat insulation, applicable compressive property and exceptional processing feature of special-shaped components. We also find an emergent phenomenon that the addition of PVA may steer desirable orientation shrinkage and linear elasticity at low strain in terms of chitosan aerogel. |

|||

| Coffee Break 10:30 – 11:00 | |||

| 11:00 to 11:20 | 10-3 | Evaluation of chitosan aerogels for application in aeronautics Philipp Niemeyer, Timothy Goller, Lorenz Ratke, Barbara Milow |

|

|

The traditional way of CO2removal from aircraft cabins via dilution is considered as an outdated technology due to negative economic and environmental impact. Developments in nanostructured chitosan aerogels for selective CO2adsorption open up new perspectives for climate control strategies. Considering industrial requirements in terms of productivity and throughput the JetCutter technology was used right from the beginning of development. Chitosan bead generation was performed at bench scale with throughput rates of 75+ kg/h. After regeneration of the chitosan gel beads chemical functionalization was performed by grafting polyethyleneimine (PEI) and phenylenediamine (PDA) onto the nanostructured gel backbone. Established drying with super critical CO2was used to produce materials of pronounced mesoporosity. Functionalized chitosan aerogel beads were characterized according to aerogel standards. In addition dynamic breakthrough measurements were performed with an atmosphere of 2500 ppm CO2in nitrogen. Scanning electron microscopy revealed homogeneous and expanded three dimensional interconnected fibrillary nanostructures. Pore size distributions and specific surface areas matched typical values for chitosan aerogels. Optical image analysis gave monodisperse particle size distribution. Packing densities were calculated to be above 65 %. Fourier transform infrared spectrometry performed on different stages during functionalization proved successful linkage between chitosan and PEI/PDA. Within the presentation requirements for onboard environmental control systems (ECS) and possible benefits from using aerogel filter materials will be explained. Also results of dynamic breakthrough measurements with binary gas mixtures and results from static physisorption experiments will be compared. Different pretreatments and their consequences for application in aeronautics will be discussed as well as competing materials already used in ECS onboard the International Space Station.

|

|||

| 11:20 to 11:40 | 10-4 | Self-assembly of cellulose in super-cooled ionic power-law fluids: A facile approach towards novel anisotropic cellulose II aerogels Sven Plappert, Jean-Marie Nedelec, Harald Rennhofer, Helga Lichtenegger, Sigrid Bernstorff, Falk Liebner |

|

|

Biopolymer-based aerogels constitute an emerging class of materials whose intriguing properties including low weight, high interconnected porosity and large specific surface literally invite to be used in a multitude of applications. Cellulose II lyogels and aerogels are of particular interest in this respect as cellulose is abundant, has a largely homogeneous macromolecular structure and requires comparatively facile methods only for processing into gels and aerogels. However, controlling and fine-tuning of the properties of lightweight cellulose II gels and aerogels is hitherto still a challenge and barely solved, even though systematic studies have shown that both the cellulose solvent and anti-solvent decide about the type of phase separation occurring during cellulose coagulation and have thus a great influence on the type of nanostructure formed. This paper reports a novel, simple and energy efficient route towards anisotropic cellulose II gels of controlled nanomorphology employing diffusion-driven gradual molecular self-assembly in an appropriate templating cellulose solvent whose nature will be revealed at the aerogel seminar only. Resulting anisotropic nanoscale gel morphologies extending to the macroscale were studied by 2D sample mapping of aerogels cross-sections with small-angle scattering experiments conducted at BOKU Viennaand the Elettra Synchrotrone Center Triest. Furthermore polarized light microscopy and FEG-scanning electron microscopy were employed to obtain a comprehensive picture of the resulting anisotropic structure. Preferred structural orientation of the nanofibrillar network structure parallel to the coagulation front was revealed. As this particular onion-like gel structure can be fully preserved throughout solvent exchange and supercritical carbon dioxide drying, the presented approach bears a great potential for the manufacture of a novel family of bio-based aerogels featuring complex morphologies. |

|||

| 11:40 to 12:00 | 10-5 | Strain hardening and pore size harmonization by uniaxial densification: A facile approach towards superinsulating aerogels from nematic nanofibrillated 2,3-dicarboxyl cellulose Sven Plappert, Jean-Marie Nedelec, Harald Rennhofer, Helga Lichtenegger, Julien Jaxel, Falk Liebner |

|

|

Development, promotion and large-scale market introduction of thermal superinsulating materials from renewable resources is a key mission of recent resource utilization, energy saving and environment protecting strategies. Considering the huge global demand for high-performance insulation materials, cellulose as abundant and easily accessible biopolymer would be a highly desired source material in this regard. Cellulose is one of the oldest insulation materials used in various forms such as loose-fill, wet-spray, stabilized or low-dust cellulose. Monolithic cellulose II aerogels however have hitherto not yet succeeded to conquer the superinsulator boundary (25 mW m-1K-1). This study now reports a break-through as it has been demonstrated at the example of 2,3-dicarboxyl cellulose (DCC) that superinsulating materials (18 mW m-1K-1) of outstandingly good mechanical performance (Eρ164 MPa cm3g-1)can be obtained by uniaxial densification of ductile ultra-lightweight nematic aerogels from any type of nanofibrillated (nf) cellulose carrying a sufficient amount of negative surface charges (e.g., 1 mmol g-1COO-). Intriguingly, uniaxial compression down to 5 % of the original aerogel volume largely preserves nematic orientation, transparence and interconnected porosity. Simultaneous with strain hardening uniaxial compression drastically reduces the count of macropores in favor of a narrow mesopore size distribution which is a prerequisite to thermal superinsulation. Moisture resistance can be imparted to DCC aerogels by conformal coating using PMMA. |

|||

| 12:00 to 12:20 | 10-6 | Cellulose aero/xerogels for moisture sorption Fernando Alvarado and Lennart Salmén |

|

|

In everyday life, the humidity of the air and thus the moisture content of matters have a profound influence on our comfort and the ability to utilise materials. The possibilities for regulating and/or absorbing moisture is therefore highly interesting. Cellulose aero/xerogel particles are here an interesting material, due to its high capability of directly adsorbing moisture by its large content of hydroxyl groups. In general, the number of hydroxyls and acidic groups, as for instance carboxylic acid groups, control moisture adsorptivity in these types of materials. In order to produce cellulose aero/xerogel particles the cellulose is dissolved in alkali and then regenerated in a coagulation bath. Utilising the jet-cutter technique the production of regular, small gel particles in large quantities is possible. By blending the cellulose with quantities of charged polysaccharides the sorption capacity as well as the stiffness of the particles may be regulated. Of importance is the coagulation which may be made in a media which not causes crystallization of the cellulose thus ensuring its high moisture sorbing capacity. The gel particles may be dried either by super critical CO2producing aerogels or just in air producing xerogels. It is here demonstrated that although aerogel particles have an enormously larger specific surface area than the xerogel particles the moisture sorbing capacity is almost the same. This is due to the fact that moisture adsorptivity is only controlled by the available number of sorption sites on the molecular scale. It is also shown that the cellulose xerogel particles maintain their sorption capacity and mechanical stability for a number of humidity cycles, i.e. they stay in their amorphous form and are not recrystallizing due to the exposure to moisture. The relation between the composition and properties of these xerogel particles is further dealt with. |

|||

| 12:20 to 12:40 | 10-7 | Cellulose aerogels – shaping and properties for tailored application Lucile Druel, Amelie Kenkel, Philipp Niemeyer, Victor Baudron, Barbara Milow, Tatiana Budtova |

|

|

Bio-aerogels are a new generation of porous materials made from polysaccharides. They show high porosity (> 90 %), high specific surface area (200 – 500 m2.g-1) and low density (around 0.1 g.cm-3). All these properties place them as good candidates for multiple applications in diverse fields such as drug delivery systems for medical applications or thermal insulating materials in buildings. Thus far, most of the produced aerogels were shaped in form of monoliths of a few cubic centimetres of volume for easy handling in laboratory preparations. However, several applications have specific requirements in terms of shape and size and aerogels should more often be shaped as beads or particles. In addition, all steps of the process (solvent exchange, drying) are much quicker when samples are of sub-millimetre size. The challenge of our work was to produce cellulose aerogel beads of different sizes, from few microns to few millimetres, and study their structure and properties. Hence, we have explored different techniques to make cellulose beads: from the simple “dropping” technique to the more advanced emulsion method as well as the larger scale Jet-Cutting. The limitations and advantages of each method will be discussed. Cellulose solvent as well as preparation conditions were adapted for each shaping technique. Cellulose beads size varied from few microns to few millimetres and their properties were similar to those of monoliths’: low density (from 0.04 to 0.1 g.cm-3) and high specific surface area (up to 450 m2.g-1). |

|||

| 12:40 to 13:00 | 10-8 | Collagen based aerogels as promising biomaterials for bone tissue engineering Lovskaya D.D., Menshutina N.V. |

|

|

Today, the problem of replacement of various defects of bone tissue, such as fractures, cracks and others, is especially acute. Modern strategies of regenerative medicine are aimed at restoring the architecture of pathologically altered tissue by replacing the bone defect with an implant placed in the area of injury. This approach allows to shorten the period of patient recovery, thereby ensuring the improvement of the quality of life. Thus, an important task is to create such a material that would be able to match the characteristics of the original bone tissue, would not elicit an immune response and would allow the growth of its own cells for the speedy regeneration of damaged bone tissue. The basis of the bone are collagen fibers, respectively, an interesting task is to obtain a porous material based on collagen, with characteristics as close as possible to human bone. One of the most promising materials for creating a bone implant is aerogel based on collagen. A collagen based aerogel possesses a number of properties that are required for an ideal bone implant: a high specific surface area (over 400 m2/g), high porosity (up to 90%), biocompatibility with bone tissue. Separately it is worth noting that due to its unique properties, aerogel can be an ideal matrix for the growth of osteoblasts – cells of bone tissue. This advantage will allow using own cells of the patient’s bone tissue, placed in the aerogel, in order to accelerate the regenerative process by the proliferation of own cells. This will also reduce the risk of an immune response. In this work, studies have been carried out to obtain aerogels based on collagen, their physicochemical properties and characteristics have been studied. The possibility of using these aerogels for replacement of defects in bone tissue has been investigated. It is shown that collagen aerogels obtained are very promising materials for use in tissue engineering. |

|||

| 13:00 to 13:30 | Poster Prize; Advapore Prize; Concluding remarks | ||

| Closing of the Seminar | |||

Download the Seminar Program here.

A list of all accepted contributions can be found here

For more information on the Advanced Porous Materials PhD award click here

Leave a reply

You must be logged in to post a comment.