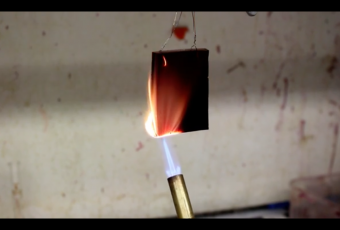

Airloy® X114 from Aerogel Technologies is a new high-strength aerogel that survives the flammability tests required for aviation and aerospace applications. With a density 3-6x lighter than plastics or composites, Airloy X114 combines strength, lightness, superinsulation, and non-flammability properties into one amazing new material. In this video, Airloy X114-H, with a density of 0.4 g/cc, is subjected to a 60-sec vertical burn test and a direct propane torch test to determine how the material will respond in a fire. Materials that survive 60 seconds without propagating flame, dripping, or smoking are good candidates to pass the FAA 25.853 burn certification requirements for aviation interiors. Airloy X114 is also machinable, has a thermal conductivity as low as 20.7 mW/m-K, and stifles transmission of sound 10-1000x better than conventional materials, including polyurethane foam.

Check out the most amazing materials of the future! This top 10 list of the strangest and coolest materials shows that science is getting very futuristic nowadays!

Aerogel Technologies manufactures advanced lightweight multifunctional materials to solve the world’s grand challenges and enable space-faring civilization. Recently our company has brought to market a new class of incredible materials we call Airloy® Ultramaterials that combine the lightness and materials properties superpowers of aerogels with the strength and durability expected of engineering materials. Airloys are 3-15x lighter than plastics or composites, up to 50% better insulating than expanded polystyrene, and 10-1000x more soundproofing than any other material, providing a unique valuable proposition anywhere weight and cost are coupled and representing a revolutionary platform technology useful for a wide variety of applications. Thanks to a breakthrough in aerogel manufacturing technology developed by Aerogel Technologies, Airloys can be made in the sizes and quantities demanded by the most challenging technology applications at a fraction of the cost of traditional aerogel materials. From airplane interiors to automotive components to engineering materials, Airloys represent a truly disruptive technology with properties unlike anything else. In this video, learn about our company and its technologies and discover how aerogel can help you engineer limitless possibilities.

As the nanotechnologies industry continue to advance, researchers are gaining the abilities to produce materials that are 90-98% air, commonly referred to as Aerogels and Airloys. These materials are the world’s best thermal insulators, conductors, and have some of the highest strength to weight ratios of any material ever.

Let’s look into what makes these materials so great and what they might be capable of in the future.

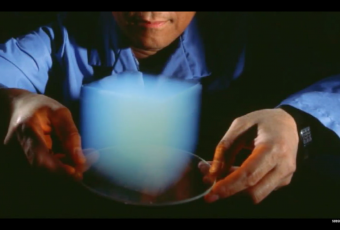

It looks like frozen smoke. And it’s the lightest solid material on the planet. Aerogel insulates space suits, makes tennis rackets stronger and could be used one day to clean up oil spills. Lawrence Livermore National Laboratory scientist Alex Gash shows us some remarkable properties of this truly unique substance.

12th International Symposium on

Supercritical Fluids

About the Conference:

The 12th International symposium on supercritical fluids, organized by the International Society for Advancement of Supercritical Fluids (ISASF), will be held on April 22 – 25 2018 in ANTIBES – JUAN – LES – PINS (France).

Topic of the conference will be the most recent scientific and technological developments in supercritical fluid technology, while special focus will be given to case studies, investigating the scale-up from lab experiments to manufacturing-scale processes, in all types of industrial fields such as:

- Food and nutraceuticals

- Cosmetics and perfumes

- Pharmaceuticals

- Medical devices and implants

- New bio-analyzers

- Electronic micro – /nano – systems

- Insulation and building materials

- Ceramics and polymers

- Defence applications

- Waste destruction and recycling

- Green chemistry

Speakers:

TBA

Symposium chair:

Dr. Michel PERRUT, Atelier Fluides Supercritiques,

Scientific Committee:

- Dr. Tadafumi ADSCHIRI, Tohoku University, Sendaï (Japan)

- Pr. Elisabeth BADENS, Aix-Marseille Université (France)

- Dr. Owen CATCHPOLE, Callaghan Innovation, Auckland (New Zealand)

- Pr. Maria-José COCERO, Universidad de Valladolid (Spain)

- Dr. Rita DUARTE, Universidade de Minho (Portugal)

- Pr. Jacques FAGES, Ecole des Mines, Albi (France)

- Pr. Motonobu GOTO, Nagoya University (Japan)

- Pr. Stephen HOWDLE, University of Nottingham (United Kingdom)

- Pr. Buxing HAN, Chinese Academy of Sciences, Beijing (China)

- Dr. Jerry KING, CSF & University of Arkansas, Fayetteville (USA)

- Pr. Erdogan KIRAN, Virginia Tech, Blacksburg (USA)

- Dr. Eduard LACK, NATEX (Austria)

- Pr. Youn-Woo LEE, Seoul National University (South Korea)

- Dr. Stephane SARRADE, CEA, Saclay (France)

- Pr. Irina SMIRNOVA, Technische Universität Hamburg-Harburg (Germany)

- Pr. Sara SPILIMBERGO, Università di Padova (Italy)

- Pr. Feral TEMELLI, University of Alberta, Edmonton (Canada)

- Pr. José Del VALLE, Pontificia Universidad Catolica de Chile, Santiago (Chile)

- Dr. James WATKINS, University of Massachussets, Amherst (USA)

- Pr. Eckhard WEIDNER, VTP Ruhr Universität, Bochum (Germany)

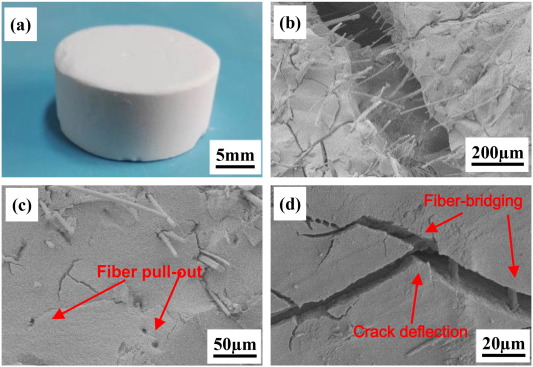

Fragility and brittleness have always been flaws of delicate three-dimensional aerogel structures. Especially when exposed to harsh conditions (e.g. in aerospace applications), their frailty has limited the broad application of aerogels in such fields. A Chinese team of researchers from the Beijing Jiaotong University has now attended to this matter. By equipping a ZrO2–SiO2 aerogel with Polycrystalline ZrO2 fibers (ZrO2f), aerogels possessing high thermal and mechanical resilience have been devised. Astonishingly, these monolithic aerogels do not only excel in terms of stability, but also show low bulk densities and thermal conductivities.

The idea of adding a fibrous agent to the aerogel matrix is that, when dispersed evenly throughout the matrix, the fibers act as an additional mechanical backbone. This means that the fibers hinder fracturing and irreversible deformation through fiber-bridging and crack-deflection (see Figure below) when the monolithic structure is being strained. Furthermore, due to the even dispersion of the fibers in the aerogel matrix, the contribution of heat conduction through the fibers is minimized and hence the overall heat conductivity increases only marginally upon addition of the fibrous ZrO2.

In summary, these effects lead to highly insulating aerogels possessing compressive strengths 3-10 times higher than previously reported. Therefore, applications in very demanding environments are facilitated, which might prove to be significant in aerospace engineering and other fields in which stable and highly insulating materials are essential.

More details: Xianbo Hou, Rubing Zhang and Daining Fang; An ultralight silica-modified ZrO2–SiO2 aerogel composite with ultra-low thermal conductivity and enhanced mechanical strength, Scripta Materialia Volume 143, 15 January 2018, Pages 113-116. http://doi.org/10.1016/j.scriptamat.2017.09.028

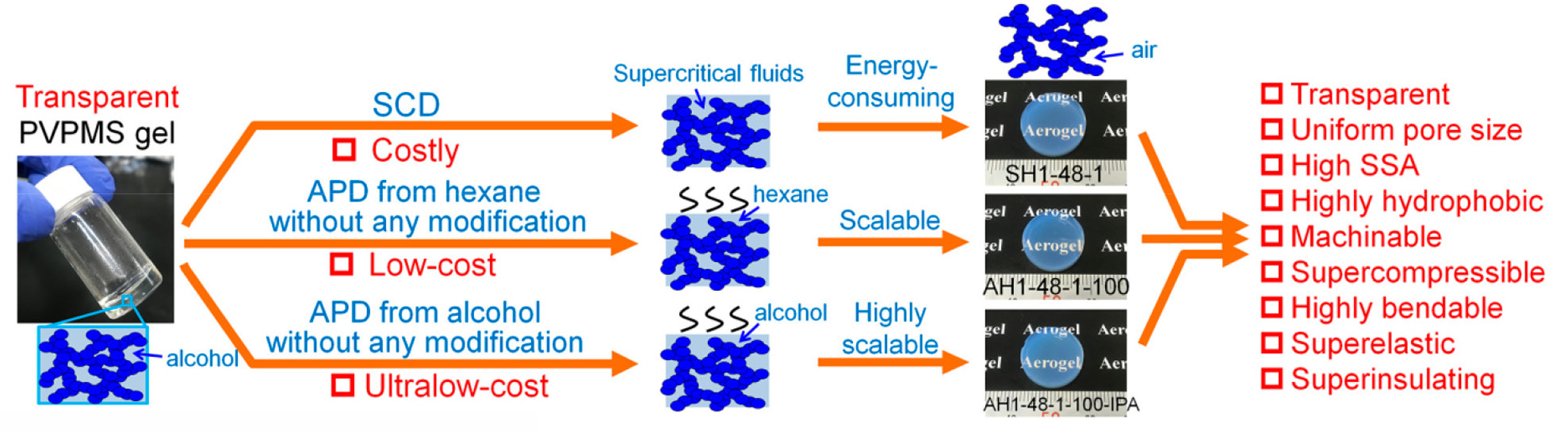

Researchers from the Kyoto University (Japan) successfully synthesized transparent, machinable, scalable, super-compressible, highly elastic and super-insulating polyvinylpolymethylsiloxane aerogels and xerogels. Remarkably, the study reports that these outstanding features were present not only in aerogels produced using supercritical drying, but in those produced using ambient pressure drying, too.

The sample preparation was achieved by mixing vinylmethyldimethoxysilane (VMDMS) or vinylmethyldiethoxysilane (VMDES) with 1-5 % of di-tert-butyl peroxide (DTBP), to initiate the radical polymerization at 120 °C, yielding a transparent viscous liquid mainly containing polyvinylmethyldimethoxysilane (PVMDMS) or polyvinylmethyldiethoxysilane (PVMDES). Thereafter, BzOH, H2O and tetramethylammonium hydroxide (TMAOH) were added to the liquid and the mixture was heated to 80 °C for one hour to obtain transparent and flexible gels. Prior to solvent exchange with isopropanol (IPA), the gels were aged between four or five days at 80-100 °C. Removal of the liquid was subsequently accomplished in three different ways (see Figure below): (1) supercritical drying with CO2; (2) solvent exchange into n-hexane followed by drying at ambient pressure; (3) direct drying from IPA at ambient pressure.

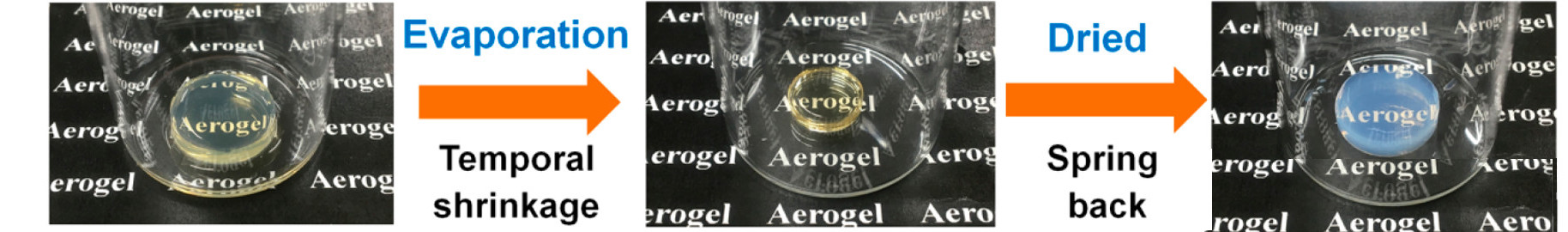

It was established that key to the intriguing properties of the dried aerogels and xerogels are their homogeneous porous nanostructure, composed of flexible hydrocarbon chains chemically cross-linked with polymethylsiloxanes. Notably, this type of nanostructure structure exhibited low densities (0.16-0.22 g/cm3) and heat conductivities (15.0-15.4 mW/m K), as well as high specific surface areas (900-1000 m2/g), good transparency (>80 % light transmittance), and extraordinary flexibility (see attached video). Additionally, the flexible network structures allowed for a recovery of the evaporation-induced gel shrinkage through a “spring-back” effect (see Figure below), making the supercritical drying step dispensable.

In summary, these findings imply that an ultra-low cost pathway to manufacture aerogels by ambient pressure drying while still preserving extraordinary properties required for applications as superinsulators has been established. This means that one of the main obstacles for the broad application of aerogels — their high manufacturing costs — has been overcome, which might pave the way for their large scale deployment.

More details: Zu et al.; Transparent, Superflexible Doubly Cross-Linked Polyvinylpolymethylsiloxane Aerogel Superinsulators via Ambient Pressure Drying , ACS Nano, January 8, 2018. https://doi.org/10.1021/acsnano.7b07117

Video of aerogel bending test: Click Here

The search for active yet economical water purification strategies is in full swing as increasing industrial activity results in sharp surges in wastewater production, and the ever-growing global population increases demand for clean drinking water.

Commonly, separated, sophisticated absorption processes are deployed to remove either organic or inorganic contaminants from sewage water due to their high efficiency and moderate cost. However, it remains a challenge to devise robust, efficient and economical absorbents for the wide range of trace elements occurring in wastewater. Ideally, novel absorption materials should be able to remove inorganic compounds such as dyes or heavy metals and also be active against harmful viral or bacterial pathogens.

In pursuit of such a material, researchers from Jinan University (China) have synthesized an aerogel structure exhibiting extraordinary dye and heavy metal absorbing properties, by using graphene oxide (GO) and a type of abundant mineral called montmorillonite (MMT). The desired anti-pathogenic activity was realized through equipping the aerogel matrix with a common anti-bacterial agent, resulting in absorbents displaying excellent antibacterial activity against Gram-positive and Gram-negative bacteria.

The aerogel material exhibiting these intriguing properties was manufactured through mixing GO powder, ascorbic acid, and a MMT solution, then inducing gelation through heat treatment at 95 °C. After aging of the hydrogel in a PVA solution for two days, the gel was then freeze dried at -55 °C, resulting in a monolithic aerogel structure, which is shown in the Figure below.

Absorption experiments showed that the aerogel absorbents were not only able to remove more than 95 % of methyl orange and methylene blue dyes from aqueous solutions, but also exhibited great properties for the removal of heavy metals from water (e.g. >90 % removal efficiency for chromium ion removal). This activity was found to be stable over numerous absorption/desorption cycles, with sample regeneration being achieved by vigorous shaking. Furthermore, the addition of antibacterial dodecyl dimethyl benzyl ammonium chloride (1227) to the initial precursor solution was found to provide the aerogel with antibacterial activity, which was shown using E. coli and S. aureus bacteria cultures, each losing over 90 % of their cell viability in the presence of the GO-MMT-1227 aerogel material.

Due to these extraordinary findings, the researchers are confident that they have found an efficient, versatile, recyclable, and robust absorbent material, which has the potential to revolutionize water purification. If economical large scale manufacturing and long term stability can be achieved, the novel material might indeed replace state-of-the-art sorbents in wastewater treatment systems.

More details: Yunyun Zhang et al.; The utilization of a three-dimensional reduced graphene oxide and montmorillonite composite aerogel as a multifunctional agent for wastewater treatment, RSC Adv., 2018,8, 4239-4248. https://doi.org/10.1039/C7RA13103H

The enhancing effects of polyaniline (PANi) coatings on ion and electron conductivity are well known (see also here), which is why researchers from the Sun Yat-sen University (China) devised PANi-coated activated carbon/sulfur aerogels (ACA-500-S) in order to improve the electrochemical properties of the un-coated composite. By synthesizing this novel electrode material, the research team hopes to address drawbacks of Li-S batteries (e.g. low ionic conductivity, dissolution of polysulfides in electrolytes).

Carbon/sulfur composite aerogels were produced by heat-melting state-of-the-art activated carbon aerogels (ACA-500) in the presence of elemental sulfur. As shown in the Figure below, the PANi coating was subsequently applied by in-situ chemical oxidative polymerization at low temperatures, yielding the final ACA-500-S@PANi electrode material. Investigation of the sample morphology via FESEM and TEM revealed that the manufacturing technique led to a homogeneous distribution of sulfur and PANi on the aerogel surface. Because of the even dispersion of the active agents on the aerogel matrix, enhanced electrochemical performance was expected from the ACA-500-S@PANi composite.

This expectation was confirmed in ensuing experiments, which compared the specific capacity, capacity discharge, and capacity retention of the ACA-500-S and ACA-500-S@PANi materials. It was shown that the latter material outperformed the carbon/sulfur aerogel in all regards, which was attributed to the synergistic effect of the carbon aerogel matrix and the PANi coating on ion and electron conductivity as well as electrode stability. More specifically, the researchers discovered that the ACA-500-S@PANi structure presented high reversible capacities at low (at 0.2 C: 1208 mAh g−1) and high (at 3.0 C: 542 mAh g−1) discharge rates. Furthermore, long term cycling at 1.0 C demonstrated that it exhibits a notable initial discharge capacity of 926 mAh g-1 and outstanding capacity retention of over 65 % at a low capacity decay rate of 0.48 ‰ per cycle.

Because of these findings, the researchers are confident that the novel aerogel composite will be able to boost the performance of lithium-sulfur batteries, meeting the increasing demand for batteries exhibiting a high energy density and long life span at low cost.

More details: Tang et al.; Polyaniline-Coated Activated Carbon Aerogel/Sulfur Composite for High- performance Lithium-Sulfur Battery, Nanoscale Research Letters 2017. https://doi.org/10.1186/s11671-017-2372-6