What is Aerogel?

Introduction

This is an aerogel.

And so is this.

A flexible, mechanically strong silica aerogel made from methyltrimethoxysilane (image credit Prof. Venkateswara Rao)

And so are these.

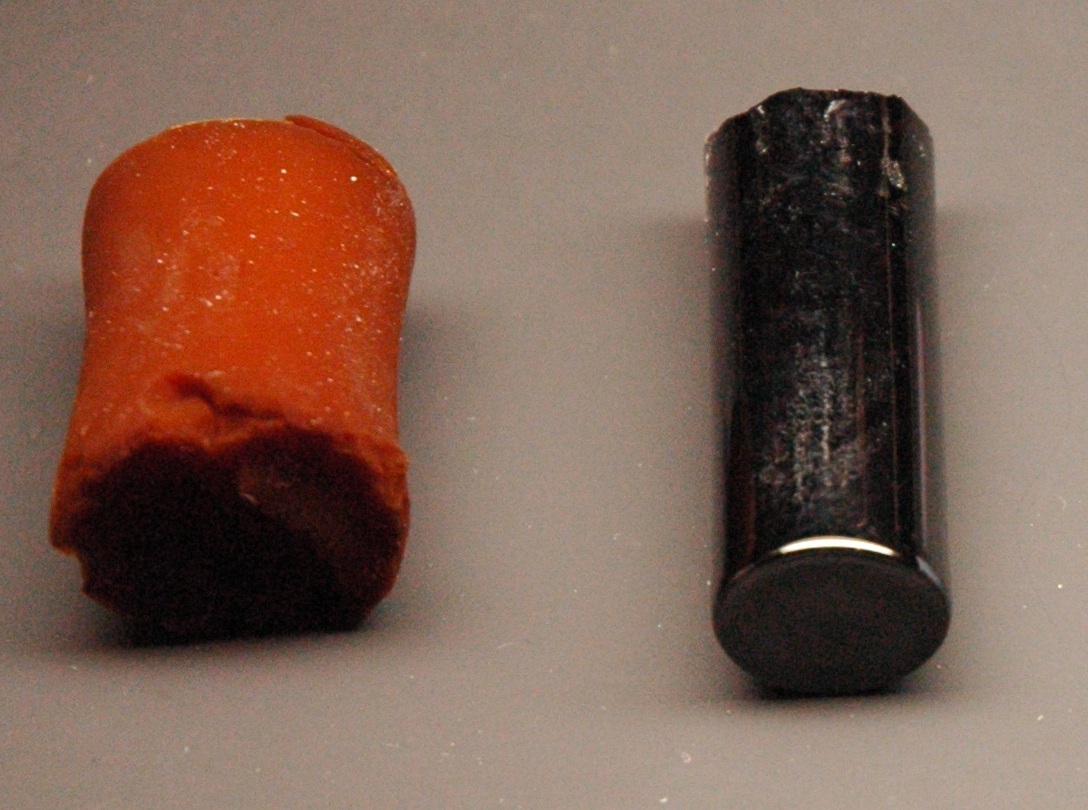

A resorcinol-formaldehyde polymer aerogel (left) and an electrically-conductive carbon aerrogel (right)

And so are these.

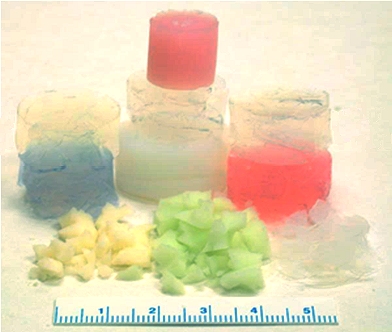

Colorful lanthanide oxide aerogels made by epoxide-assisted gelation of metal salts (image credit Lawrence Livermore National Laboratory)

Transition metal oxide aerogels including an iron oxide (rust) aerogel (top) (image credit Lawrence Livermore National Laboratory)

Aerogels are a diverse class of porous, solid materials that exhibit an uncanny array of extreme materials properties. Most notably aerogels are known for their extreme low densities (which range from 0.0011 to ~0.5 g cm-3). In fact, the lowest density solid materials that have ever been produced are all aerogels, including a silica aerogel that as produced was only three times heavier than air, and could be made lighter than air by evacuating the air out of its pores. That said, aerogels usually have densities of 0.020 g cm-3 or higher (about 15 times heavier than air). But even at those densities, it would take 150 brick-sized pieces of aerogel to weigh as much as a single gallon of water! And if Michaelangelo’s David were made out of an aerogel with a density of 0.020 g cm-3, it would only weigh about 4 pounds (2 kg)! Typically aerogels are 95-99% air (or other gas) in volume, with the lowest-density aerogel ever produced being 99.98% air in volume.

Essentially an aerogel is the dry, low-density, porous, solid framework of a gel (the part of a gel that gives the gel its solid-like cohesiveness) isolated in-tact from the gel’s liquid component (the part that makes up most of the volume of the gel). Aerogels are open-porous (that is, the gas in the aerogel is not trapped inside solid pockets) and have pores in the range of <1 to 100 nanometers (billionths of a meter) in diameter and usually <20 nm.

Aerogels are dry materials (unlike “regular” gels you might think of, which are usually wet like gelatin dessert). The word aerogel refers to the fact that aerogels are derived from gels–effectively the solid structure of a wet gel, only with a gas or vacuum in its pores instead of liquid. Learn more about gels, aerogels, and how aerogels are made.

Technical Definition

By definition,

An aerogel is an open-celled, mesoporous, solid foam that is composed of a network of interconnected nanostructures and that exhibits a porosity (non-solid volume) of no less than 50%.

The term “mesoporous” refers to a material that contains pores ranging from 2 to 50 nm in diameter.

Generally speaking, most of the pores in an aerogel fall within this size range. In practice, most aerogels exhibit somewhere between 90 to 99.8+% porosity and also contain a significant amount of microporosity (pores less than 2 nm in diameter).

What Are Aerogels Made Of?

The term aerogel does not refer to a particular substance, but rather to a geometry which a substance can take on–the same way a sculpture can be made out of clay, plastic, papier-mâché, etc., aerogels can be made of a wide variety of substances, including:

- Silica

- Most of the transition metal oxides (for example, iron oxide)

- Most of the lanthanide and actinide metal oxides (for example, praseodymium oxide)

- Several main group metal oxides (for example, tin oxide)

- Organic polymers (such as resorcinol-formaldehyde, phenol-formaldehyde, polyacrylates, polystyrenes, polyurethanes, and epoxies)

- Biological polymers (such as gelatin, pectin, and agar agar)

- Semiconductor nanostructures (such as cadmium selenide quantum dots)

- Carbon

- Carbon nanotubes

and

- Metals (such as copper and gold)

Aerogel composites, for example aerogels reinforced with polymer coatings or aerogels embedded with magnetic nanoparticles, are also routinely prepared.

Learn more about the different flavors of aerogels that exist.

Aerogel vs. Silica Aerogel

The term aerogel when used by itself is frequently used to refer specifically to silica aerogels like the blue one shown in the first picture above (although this is like saying “plastic” and specifically meaning, say, polyethylene, despite the fact that there are many other types of plastic such as polypropylene, acrylic, Teflon®, Nylon®, etc.). In general, the aerogel of a substance is chemically similar to the bulk form of that substance. This said, due to their low densities and length-scale effects arising from having nanostructured features, aerogels often exhibit many dramatically enhanced materials properties over the non-aerogel form of the same substance (for example, significant increases in surface area and catalytic activity), while frequently also exhibiting reductions in other materials properties (such as mechanical strength).

Special Properties of Aerogels

Many aerogels boast a combination of impressive materials properties that no other materials possess simultaneously. Specific formulations of aerogels hold records for the lowest bulk density of any known material (as low as 0.0011 g cm-3), the lowest mean free path of diffusion of any solid material, the highest specific surface area of any monolithic (non-powder) material (up to 3200 m2 g-1), the lowest dielectric constant of any solid material, and the slowest speed of sound through any solid material. It is important to note that not all aerogels have record properties (in fact most don’t, although they may have very good values for many properties)!

By tailoring the production process, many of the properties of an aerogel can be adjusted. Bulk density is a good example of this, adjusted simply by making a more or less concentrated precursor gel. The thermal conductivity of an aerogel can be also be adjusted this way, since thermal conductivity is related to density. Typically, aerogels exhibit bulk densities ranging from 0.5 to 0.01 g cm-3 and surface areas ranging from 100 to 1000 m2 g-1, depending of course on the composition of the aerogel and the density of the precursor gel used to make the aerogel. Other properties such as transparency, color, mechanical strength, and susceptibility to water depend primarily on the composition of the aerogel.

For example, silica aerogels, which are the most widely researched type of aerogel (and the type people typically see in photographs), are usually transparent with a characteristic blue cast due to Rayleigh scattering of the short wavelengths of light off of nanoparticles that make up the aerogel’s framework. Carbon aerogels, on the other hand, are totally opaque and black. Furthermore, iron oxide aerogels are just barely translucent and can be either rust-colored or yellow. As another example, low-density (<0.1 g cm-3) inorganic aerogels are both excellent thermal insulators and excellent dielectric materials (electrical insulators), whereas most carbon aerogels are both good thermal insulators and electrical conductors. Thus it can be seen that by adjusting processing parameters and exploring new compositions, we can make materials with a versatile range of properties and abilities.

The Flower, the Mona Lisa of aerogel pictures, dramatically demonstrates the superinsulating properties of silica aerogel by insulating a delicate, moist flower from the raging heat of a Bunsen burner (image credit Lawrence Berkeley National Laboratory)

Aerogels of all sorts hold records for different properties. Here are some:

Records held by some specially-formulated silica aerogels:

- Lowest density solid (0.0011 g cm-3)

- Lowest optical index of refraction (1.002)

- Lowest thermal conductivity (0.016 W m-1 K-1)

- Lowest speed of sound through a material (70 m s-1)

- Lowest dielectric constant from 3-40 GHz (1.008)

Record held by a specially-formulated carbon aerogel:

- Highest specific surface area for a monolithic material (3200 m g-1)

A more in-depth discussion of the properties of silica aerogel and other historically underrepresented types of aerogel can be found in the Flavors of Aerogel section.

What Does an Aerogel Feel Like? How Strong Are They?

To the touch, an inorganic aerogel (such as a silica or metal oxide aerogel) feels something like a cross between a Styrofoam® peanut, that green floral potting foam used for potting fake flowers, and a Rice Krispie®. Unlike wet gels such as Jell-O®, inorganic aerogels are dry, rigid materials and are very lightweight.

In general aerogels are pretty fragile. Inorganic aerogels are friable and and will snap when bent or, in the case of very low density aerogels, when poked, cleaving with an irregular fracture. This said, depending on their density, aerogels can usually hold a gently applied load of up to 2,000 times their weight and sometimes more. But since aerogels are so low in density, it doesn’t take much force to achieve a pressure concentration equivalent to 2,000 times the material’s weight at a given point. The amount of pressure required to crush most aerogels with your fingers is about what it would take to crush a piece of Cap’n Crunch® cereal.

Organic polymer aerogels are less fragile than inorganic aerogels and are more like green potting foam in consistency in that they are squish irreversibly. Carbon aerogels, which are derived from organic aerogels, have the consistency of activated charcoal and are very much not squishy.

There are several examples, however, of remarkably strong aerogels that can withstand tens of thousands of times their weight in applied force. A class of polymer-crosslinked inorganic aerogels called x-aerogels are such materials and can even be made flexible like rubber in addition to being mechanically robust (see Flavors of Aerogels). One type of x-aerogel made from vanadia (vanadium oxide) is extraordinarily strong in compression with the highest compressive strength to weight ratio of any known type of aerogel and rivals that of materials such as aerospace-grade carbon fiber composites! Regardless of composition, most types of aerogel can be made stronger simply by making them denser (between 0.1 and 0.5 g cm-3), however only at the expense of their light weight and ultralow thermal conductivity.

A Note About the Spelling and Use of the Word Aerogel

Aerogel is correctly spelled just like that–aerogel–and is pronounced like “air-o-jel”. It is not a proper noun nor is it a trade name and thus should not be specially capitalized, noted with trademark, or placed in quotes in normal use. It should only be capitalized at the beginning of sentence and in titles, like other nouns. It is also not a compound word and should not be spelled with a hyphen or a space. Frequent misspellings include “AeroGel”, “aerojell”, “areogel”, “aerojel”, “aerojell”, “airojell”, “aero-gel”, “aero gel”, and “airgel”. Aerogel is occasionally referred to as “air glass” or “frozen smoke” but these are just nicknames. Brand names that refer to some commercial aerogel materials include Santocel® (obsolete), Nanogel®, Pyrogel®, Cryogel®, and Spaceloft®–each of which consists of aerogel with a different formulation and composition.

Furthemore, aerogels are most definitely not aerosols, which are colloidal sprays such as those used for hairspray.

When confronted with the question of how to properly use the word aerogel in a sentence, try replacing “aerogel” in your mind with the word “plastic” and think of how you would use that word in a similar context. For example: “plastics are useful materials” = “aerogels are useful materials”, or “plastic has greatly impacted society” = “aerogel can greatly impact society”. Additionally, a sample of aerogel can be referred to as “an aerogel”. As mentioned earlier, “aerogel” by itself is frequently used to refer specifically to silica aerogel, even though there many types of aerogels other than silica aerogel.

Lots More to Learn About!

Aerogel.org has articles about many different types of aerogels, applications of aerogels, the history of aerogel, and how-to guides on how to make aerogels yourself. There is also an interactive properties database where you can compare the physical properties of different types of aerogels side-by-side. Explore and get involved!

Next Up: Read about how aerogels are made.